Anomaly detection of core failures in die casting X-ray inspection images using a convolutional autoencoder

Diagram

DiagramAbstract

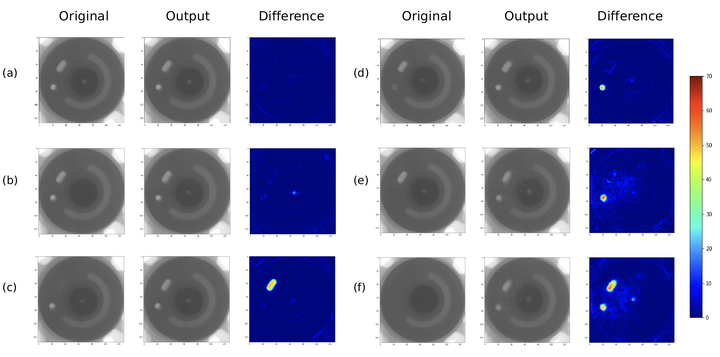

Core failure inspection is an important issue in die casting. The inspection process is often carried out by manually examining X-ray images. However, human visual inspection suffers from individual biases and eye fatigues. Computer-vision-based automatic inspection, if it can achieve equal to or better than human performance, is favored to assist the inspectors to achieve better quality control. Most existing works are heavily relied on the supervised methods, which require enormous labeling and cannot be deployed quickly and economically. This is particularly difficult for a die casting plant that has many different types of products. Labeling each type of product before applying automated inspection may not be feasible in practice. It is therefore necessary to investigate unsupervised methods for die casting products. In this research, an inspection framework built on top of convolutional autoencoder (CAE) is designed and developed to inspect core failures from real-world die casting X-ray images in an unsupervised manner. Identification of good and scrap product, and localization of the defect are achieved in a single network. The framework is designed to be easily generalized to other image inspection scenarios. The area of interest for inspection is first extracted automatically through the Hough transformation. Then the preprocessed image is inspected by CAE. The noises of the model are removed using edge detection. It achieved an impressive 97.45% classification accuracy on average, and precisely pinpointed the defect regions with a small training set of 30 images.